The Rotary Actuator: The Gear Reduction Core

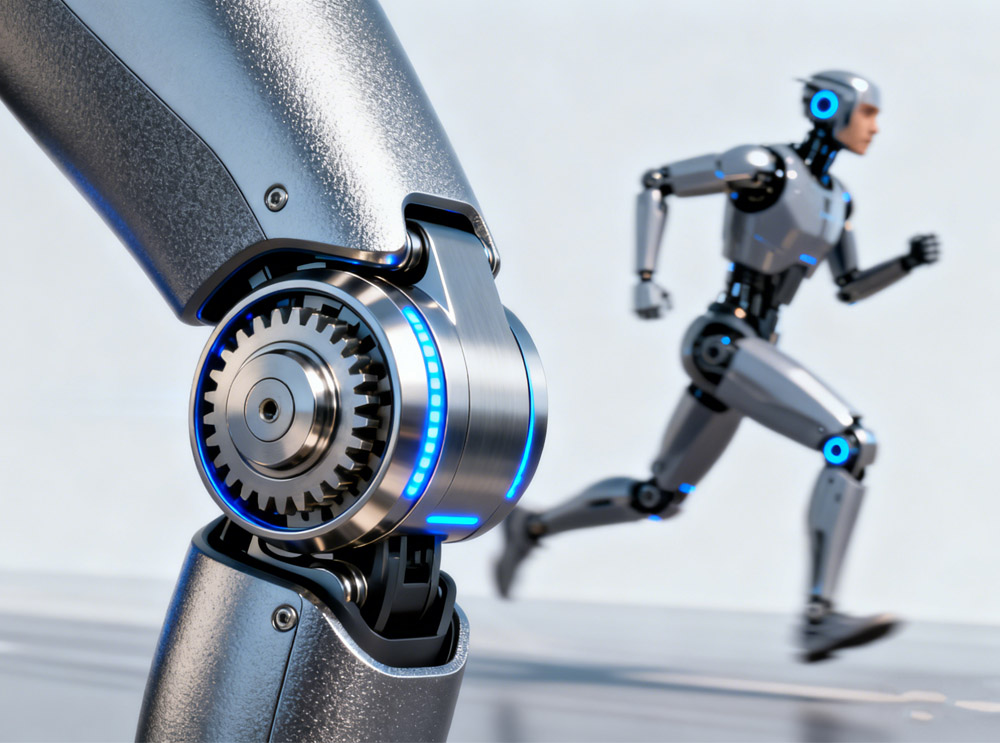

The motor spins very fast, but robots need huge torque at low speeds. That’s where the precision reduction system steps in. This system converts high speed into high torque. Choosing the right rotary actuator is the most crucial decision, as it dictates the joint’s behavior:

Harmonic Drives (Strain Wave Gears)

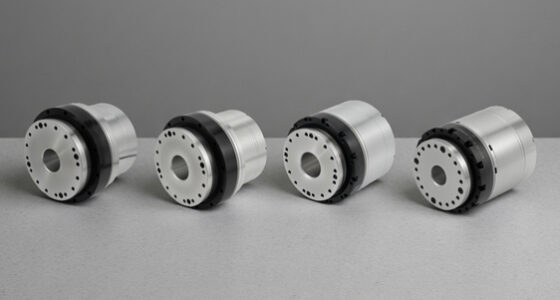

Harmonic drives (strain wave gears) are prized for their compact size, near-zero backlash, and exceptional precision. A core component enabling this performance is the cross roller bearing (CRB), which supports radial, axial, and moment loads in a single compact structure.

By integrating high-performance CRBs, Laifual’s harmonic solutions deliver high torque, high load capacity, and superior stiffness without increasing size. The even load distribution of CRBs enhances durability and smoothness, allowing harmonic drives to maintain precision under varying loads. This makes them especially suitable for collaborative robots, humanoids, and compact actuators.

Cycloidal/RV Reducers

Products like high-rigidity RV reducers (often found in advanced rotary actuator solutions) are designed differently. They distribute the load across many gear teeth at once. This multi-point contact makes them incredibly robust against shock loads and gives them superior durability. If you are building a robot’s hips or knees that must endure 24/7 operation for 6,000–10,000 hours, RV reducers are often the mandatory choice.

The Brains: Dual-Encoder Sensing

To achieve precise joint control, the joint modules rely on a dual-encoder architecture. One encoder is mounted on the motor shaft (input), while a second high-resolution encoder sits on the output shaft (load). This setup allows the system to detect gear “windup”, the tiny elastic twist that occurs under heavy load.

By comparing input and output positions in real time, the controller compensates instantly.

- Laifual supports a wide range of industry-standard communication protocols to match different robot architectures.

- For DC-type actuators, we offer CANopen, EtherCAT, and CAN-FD for humanoids, cobots, and low-voltage robotic joints.

- For AC-type actuators, we support BiSS-C and Tamagawa, preferred in industrial robots, CNC rotary tables, and high-precision automation.

These encoder protocol options not only improve compatibility and performance but also address a key concern for users evaluating harmonic actuators, rotary joints, and frameless motors.

Compliance and Cost Challenge

Old robots were stiff and purely position-controlled. But human interaction requires compliance. The joint needs to be mechanically transparent and react safely to forces, a quality called backdrivability.

Modern joint modules achieve this by combining powerful frameless motors with low-ratio transmissions. The motor’s inherent power means the gearing doesn’t have to be excessively high-ratio, which reduces friction and makes the joint easier to move by external forces.

Heat and Lifespan

In these compact modules, continuous performance is limited by heat, not power. High Km motors help, but the system must rely on passive air cooling (integrated heat sinks) to manage heat dissipation. Engineers fight to maximize efficiency just to avoid the weight and complexity of active liquid cooling.

Ultimately, the choice of a rotary actuator is a decision about longevity. It ensures the robot can handle repeated impacts and heavy loads for thousands of hours without constant maintenance.

The Advanced Joint Module is the technological sweet spot where maximum power density, high-fidelity control, and cost-saving virtual sensing all converge. By continually optimizing these integrated rotary actuators, engineers are defining the essential hardware foundation for mass-produced, high-dynamic robots.

Conclusion

The Advanced Joint Module is the technological sweet spot where maximum power density, high-fidelity control, and cost-saving virtual sensing all converge. Building a truly human-like robot isn’t about giant motors. It’s about micro-managing weight and heat while maximizing mechanical toughness.

If your current project demands high torque, rock-solid durability, and a compact design built for the long haul, you need reliable componentry that can handle continuous, high-load operation.

Ready to find the perfect “muscle” for your next generation robot? Explore the full range of robust rotary actuators and gear drives engineered for continuous, high-load operation.