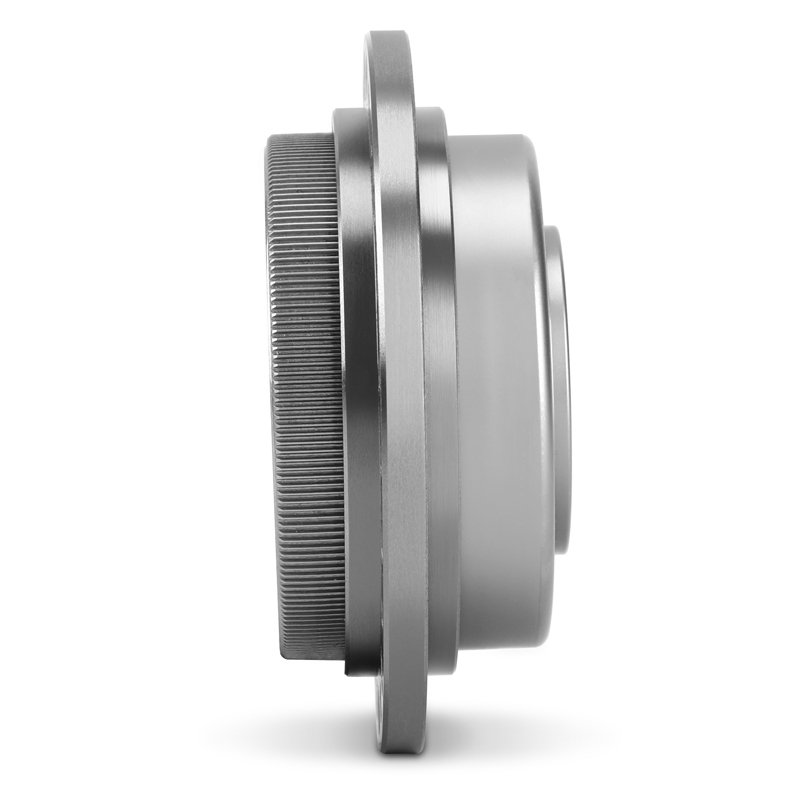

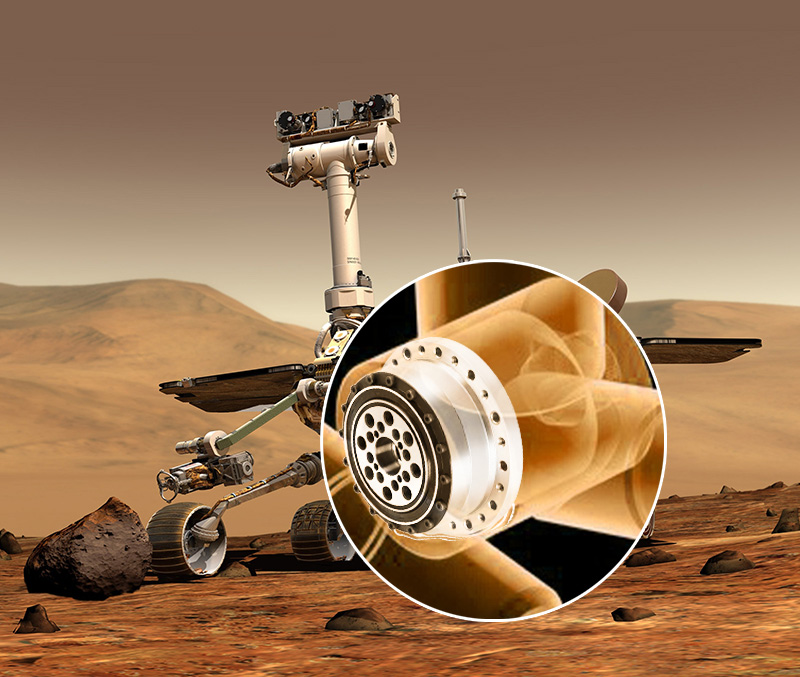

The FSG High Torque Harmonic Drive is Laifual Drive’s dedicated High Torque product line, engineered to deliver superior performance for demanding applications.

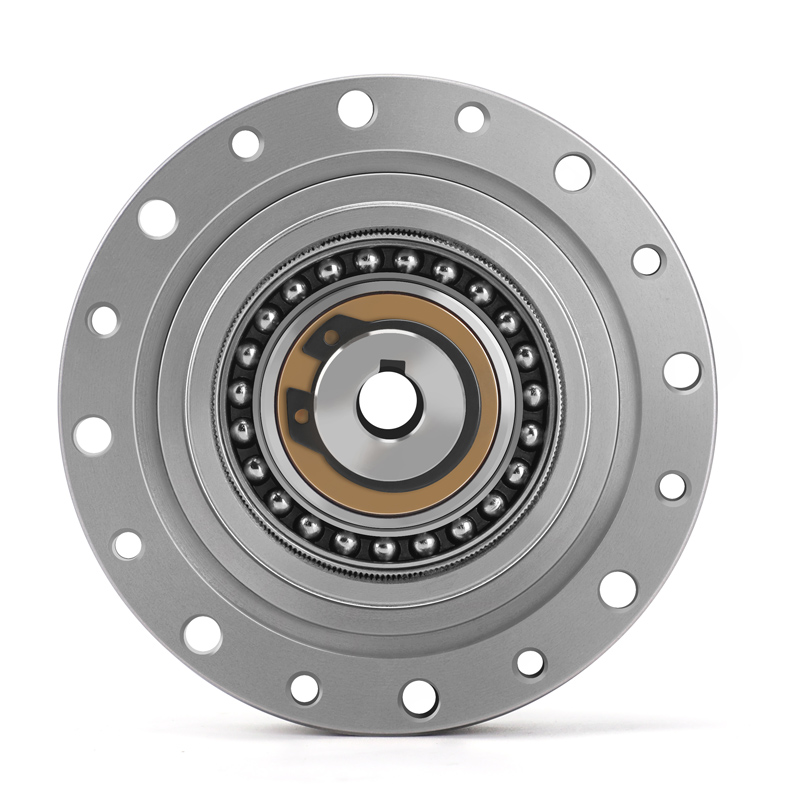

Building on the proven design of the standard series, the G Series incorporates advanced tooth profile optimization and material enhancements to significantly boost load capacity and durability.

It is the ideal solution for precision motion control requiring higher torque density and longer operational life without increasing the physical size of the gearbox.