In today’s advanced automation landscape, achieving reliable accuracy in motion control remains a common challenge. Engineers working with robotics and automated systems are often required to make careful trade-offs, as the choice of a high-precision gearbox can affect positioning accuracy, system performance, and overall cost.

As robotics transmission systems continue to move toward higher speed, greater accuracy, and more compact designs, the differences between gearbox technologies become more noticeable. This article compares two widely used high-precision gearbox solutions, outlining how their characteristics relate to practical motion control requirements.

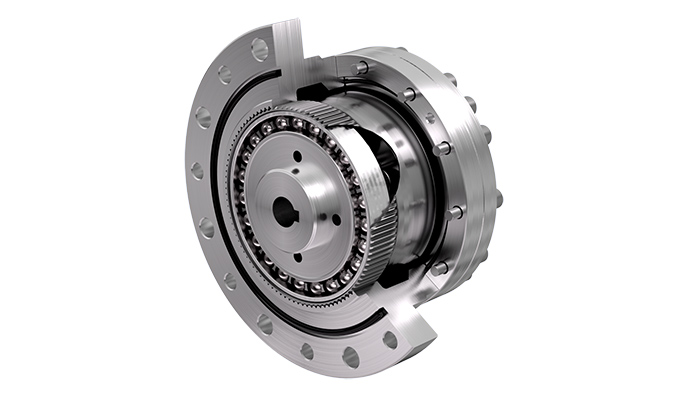

What Is a Strain Wave Gear?

A Strain Wave Gear, also known as a Harmonic Drive, is a high-precision gearbox used in applications requiring accurate positioning, compact design, and smooth motion. It is widely used in applications such as robotics, aerospace, and medical devices, where accuracy, repeatability, and space efficiency are required.

How Does a Strain Wave Gear Work?

A strain wave gear transmits motion by continuously deforming a flexible gear element so that its teeth engage the fixed gear ring at specific points. This tooth engagement pattern creates a predictable speed difference between input and output, producing smooth, accurate reduction.

Key Components of a Strain Wave Gear

Wave Generator (Input)

The wave generator is an elliptical hub with a bearing assembly. As it rotates, it forces the flexible gear element to take on an elliptical shape, driving the gear engagement process.

Flexspline (Output)

The flexspline is a thin, flexible cup with external teeth. It deforms to match the wave generator’s ellipse and meshes with the circular spline at two opposing regions along the major axis.

Circular Spline (Fixed Ring Gear)

The circular spline is a rigid ring with internal teeth and is typically fixed to the housing. It has slightly more teeth than the flexspline, enabling reduction through controlled tooth count difference.

Strain Wave Gear Operating Principle

As the wave generator rotates, it continuously reshapes the flexspline, causing its teeth to engage and disengage with the circular spline at the major axis of the ellipse. Because the circular spline has more teeth, the flexspline advances by a small number of teeth per rotation—resulting in a slow, precise, and reverse-direction output relative to the input. This is what enables high reduction ratios with smooth, repeatable motion.

Advantages of Strain Wave Gears for Motion Control

- Zero Backlash for High-Accuracy Positioning: Strain wave gears deliver true zero backlash, supporting repeatable positioning and stable control loops in precision motion control systems.

- Compact and Lightweight with High Torque Density: Their design achieves a high torque-to-size ratio, which helps reduce joint size and system weight in compact robotics transmission architectures.

- Coaxial Input and Output for Easier Integration: The coaxial layout keeps input and output on the same axis, simplifying mechanical packaging and alignment.

When a Strain Wave Gear Fits

When a project prioritizes zero backlash, compact packaging, and high reduction in a single stage, a Strain Wave Gear is a common gearbox choice for modern motion control and robotics transmission designs.

What Is a Cycloidal Drive (RV Reducer)?

A Cycloidal Drive, also known as an RV Reducer, is a heavy-duty high-precision gearbox used in applications that demand high rigidity and load capacity. It is commonly found in industrial robotics and automation systems where strength and durability matter more than compact size.

How Does a Cycloidal Drive Work?

A cycloidal drive uses the cycloidal pinwheel principle to transmit motion. Torque is transferred through rolling contact instead of sliding gear teeth. This spreads the load across multiple contact points and improves resistance to wear and shock.

Key Components of a Cycloidal Drive

Eccentric Cam (Input)

The eccentric cam is connected to the input shaft. It drives the cycloidal disc in an offset circular motion.

Cycloidal Disc

The cycloidal disc has a specially shaped profile. It engages with a ring of pins while moving in a wobbling motion.

Pin Gear Housing (Fixed Ring)

The pin gear housing contains evenly spaced pins or rollers. These pins transmit torque and share the load during operation.

Cycloidal Drive Operating Principle

As the eccentric cam rotates, it forces the cycloidal disc to move in a rolling, orbital path. The disc engages several pins at the same time. Because the disc has fewer lobes than the number of pins, a speed difference is created. This produces a slow output speed and high torque with strong mechanical stability.

Advantages of Cycloidal Drives

- High Rigidity and Torsional Stiffness: Cycloidal drives use rigid components and multi-point contact. This results in very high stiffness and minimal deformation under load.

- High Shock Load Capacity: The design allows cycloidal drives to absorb sudden impacts. They can typically handle shock loads of up to five times the rated torque, including emergency stops.

Limitations of Cycloidal Drives

- Large Size and Heavy Weight: The robust structure requires more space. Cycloidal drives are larger and heavier than strain wave gears.

- Complex Structure and Higher Cost: More components and tighter tolerances increase manufacturing and assembly complexity. This usually leads to higher overall cost.

When to Choose a Cycloidal Drive

A Cycloidal Drive (RV Reducer) is a practical choice for motion control systems that require high rigidity, strong shock resistance, and long-term reliability, especially in heavy industrial robotics and automation.

Detailed Comparison: Strain Wave vs. Cycloidal

Use this quick comparison to select the right high-precision gearbox for robotics transmission and motion control systems. Strain wave gears focus on compact precision. Cycloidal drives focus on stiffness and load durability.

| Feature | Strain Wave Gear (Harmonic Drive) | Cycloidal Drive (RV Reducer) |

| Core strength | Compact precision | Rigidity and shock resistance |

| Backlash | True zero backlash | Very low backlash (depends on design/preload) |

| Accuracy & repeatability | Excellent | Excellent (especially under heavy load) |

| Torsional stiffness | Medium to high | Very high |

| Shock load capacity | Moderate | Very high (often up to ~5× rated torque) |

| Torque density (torque/size) | Very high | High, but larger package |

| Size & weight | Small and lightweight | Larger and heavier |

| Reduction ratio (single stage) | High (commonly up to ~160:1, can be higher) | Medium to high (often lower per stage than strain wave) |

| Efficiency | Moderate to high | High (often strong at low speed/high load) |

| Wear characteristics | Flex element fatigue is a key consideration | Robust rolling contact, long service life in heavy duty use |

| Noise & smoothness | Very smooth, low vibration | Smooth under load; can be noisier than strain wave in some setups |

| Cost trend | Often high, depends on precision grade | Often higher for heavy-duty sizes and complex construction |

| Best-fit robot axes | Wrists, elbows, compact joints | Base joints, large axes, high-inertia joints |

| Typical applications | Cobots, humanoids, medical devices, optical systems | Industrial robot bases, heavy positioners, machine tools |

Engineering Selection Guide: When to Choose Which?

Selecting the right transmission is never about finding the “perfect” gear, but finding the optimal match for your specific constraints. Based on decades of application experience, here is our decision matrix to help you navigate between Strain Wave Gears and Cycloidal Drives.

Choose a Strain Wave Gear when

- You need zero backlash and high positioning accuracy

- You want the smallest and lightest high-precision gearbox

- Your robot joint is space-constrained (wrist, elbow, compact arm)

Recommendation: For applications demanding compact precision, explore Laifual’s FS & FH Series. These standard-setting units provide the ideal balance of performance and footprint.

Choose a Cycloidal Drive (RV Reducer) when

- You need high rigidity and strong stiffness under load

- Your system faces shock loads (hard stops, high inertia, impacts)

- Your axis is large and load-heavy (base joint, large rotary table, heavy positioner)

Why Laifual Drive is Your Partner for Precision

Historically, engineers chose Cycloidal drives for durability and Strain Wave gears for precision. Laifual has bridged this gap, engineering strain wave solutions that deliver high torque and longevity without sacrificing zero-backlash accuracy.

Revolutionary Tooth Profile

We shattered the torque bottleneck with our proprietary “Local Conjugate Surface Contact” design. By increasing the mesh contact area by 40%, we boosted overall load-bearing capacity by 50%. This innovation solves the conflict between torque density and lifespan, all while maintaining transmission errors below 40 arc-seconds.

Micro-Series for Humanoids (7.68g)

From dexterous fingertips to powerful shoulders, we cover every joint. Our 03 Micro-Series weighs just 7.68g, enabling ultra-compact designs. Whether you need the miniature precision of the 03/05 series or the heavy-lifting power of the 45/50 series, Laifual offers a full-spectrum solution for humanoid robotics.

Optimized Structure & Reliability (-30% Weight)

Weight defines efficiency. Through topological optimization of the cross-roller bearing, we reduced structural weight by over 30% without compromising rigidity. To ensure longevity under dynamic shock loads, we partner with Klüber Lubrication to develop custom solutions that combat vibration and the “ratcheting” phenomenon in extreme conditions.

FAQ

Q: Are harmonic drives better than cycloidal drives?

A: Not “better,” but different. Harmonic drives are better for precision and weight, while cycloidal drives are better for load capacity and stiffness.

Q: Do strain wave gears wear out?

A: Yes, over time the flexspline can experience fatigue. However, Laifual uses high-quality steel to extend service life significantly.

Q: Can a cycloidal drive have zero backlash?

A: Typically no. They have very low backlash, but strain wave gears are the only true zero-backlash mechanical solution due to their elastic design.