Key Insight

- A higher gear ratio reduces speed and increases torque.

- A lower gear ratio increases speed and reduces torque.

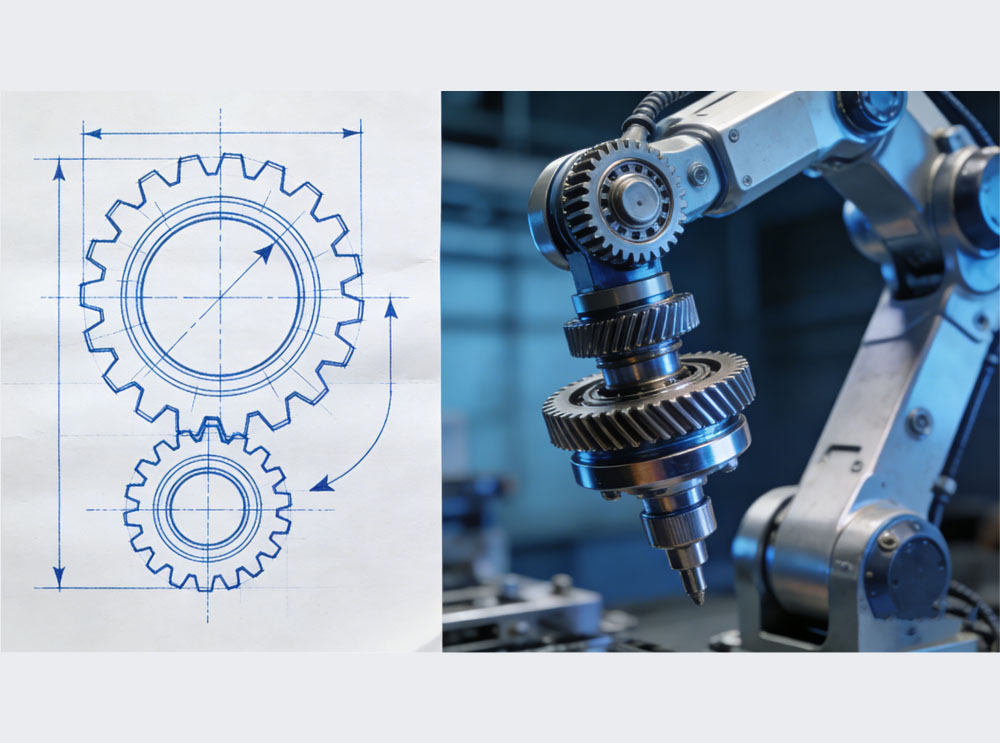

This simple relationship explains how gear systems shape motion behavior across everything from bicycles to high-precision robotics.

Speed vs. Torque: Understanding the Trade-Off

The Inverse Relationship

Speed and torque are linked by a simple physical rule: power conservation.

In rotational systems, power is defined as:

P=T×ω

Where T is torque and ω is rotational speed.

If power remains constant, reducing speed must result in an increase in torque. This is why a gearbox acts as a torque multiplier. It trades rotational speed for usable force at the output.

In practical terms, when a system slows down through gearing, torque increases by roughly the same ratio.

Why We Use Speed Reducers

Most industrial electric motors are designed to run at high speed, often around 3,000 rpm, while producing relatively low torque. High-speed motors are smaller, more efficient, and easier to control. However, robotic arms and industrial machinery require high torque at low speed.

A speed reducer, or gearbox, bridges this gap. By reducing motor speed, the gearbox multiplies torque to a level that can move heavy loads, hold position, and operate smoothly. This is why speed reducers are a core component in robotics transmission systems, enabling precise and powerful motion from compact motors.

Types of Gear Ratios in Industry

Not all gear ratios are created equal. Depending on the space available and the torque required, engineers choose different mechanical structures to achieve the desired reduction.

1. Spur Gears

Spur gears represent the most common type found in simple mechanisms like bicycles or clocks. This setup involves a small driver gear, often called a pinion, turning a larger driven gear. While effective for low reductions such as 3:1 or 5:1, they face significant limitations when higher torque is needed. Achieving a massive 100:1 ratio would require daisy-chaining multiple gears together. This results in a bulky mechanism that is heavy and prone to backlash or play between the teeth.

2. Planetary Gears

Planetary gears act as a step up in engineering complexity. This design places planet gears inside an outer ring gear to share the load across multiple teeth, offering higher torque density. They are efficient for medium reductions ranging from 10:1 to 50:1. However, reaching very high ratios typically demands stacking multiple stages together. This increases the total length of the motor assembly and introduces accumulated transmission errors.

3. Strain Wave Gears

In high-precision robotics, you don’t have space for bulky gear trains, and you cannot tolerate backlash. Enter the Strain Wave Gear.

The Magic: High Ratio in a Single Stage Unlike spur or planetary gears, Laifual strain wave gears can achieve massive reduction ratios ranging from 30:1 up to 160:1 in a single concentric stage. This capability eliminates the need to stack gears. It allows for ultra-flat profiles and lightweight designs, enabling robot joints to be powerful yet incredibly compact.

The Calculation Difference: The “2-Tooth” Rule How is this possible? The math behind strain wave gears is unique. It relies on the interaction between a non-rigid Flexspline and a rigid Circular Spline.

- The Secret: The Flexspline has exactly 2 fewer teeth than the Circular Spline.

- The Result: For every full 360° rotation of the input (Wave Generator), the Flexspline does not rotate a full circle. Instead, it moves backward by a distance of only 2 teeth.

- The Formula:

This unique mechanism allows a motor to spin at 3000 RPM while the output moves with extreme slowness and massive torque—all with zero mechanical backlash.

Why High Gear Ratios Matter in Robotics

In robotics, engineers constantly battle to balance power and size. Joints require immense torque for lifting and precision for positioning, yet standard motors inherently lack this torque. Traditional gearboxes solve this by stacking multiple gear stages, but this adds significant bulk and introduces backlash.

Laifual solves this dilemma with high-reduction strain wave gears in a single, ultra-compact stage. For instance, our 03 Series weighs just 7.68g yet delivers the massive torque multiplication needed for dexterous robotic fingers.

Conclusion

Understanding gear ratios is the foundation of mechanical design, defining the critical trade-off between speed and force. While simple spur gears suffice for basic applications where space is abundant, modern automation demands more.

If your project requires reduction ratios above 30:1 combined with restricted installation space and absolute precision, standard solutions will fall short. Laifual Strain Wave Gears offer the robust, cost-effective answer. Whether for a humanoid robot or a precision medical device, our zero-backlash technology ensures your innovation performs exactly as engineered. Explore the Laifual series today to secure the optimal drive solution for your rigorous standards.