Harmonic Drive

Engineered for excellence, Laifual harmonic reducers deliver more than just 99% performance matching to standard systems. Utilizing the precise three-part architecture, our specialized series push the limits: the High-Torque G-Series increases capacity by 30%, while the Lightweight N-Series reduces weight by over 20%. This optimized configuration guarantees zero backlash and extended service life, making Laifual the definitive choice for humanoid robotics, aerospace, and demanding industrial automation.

High-Performance Strain Wave Gears

Engineered for zero backlash and high torque density, our harmonic reducers deliver exceptional precision in a compact footprint. Featuring low starting torque and minimal temperature rise, Laifual gears ensure a long service life even under heavy loads. Backed by 10+ years of R&D, we provide high-reliability transmission solutions for advanced automation.

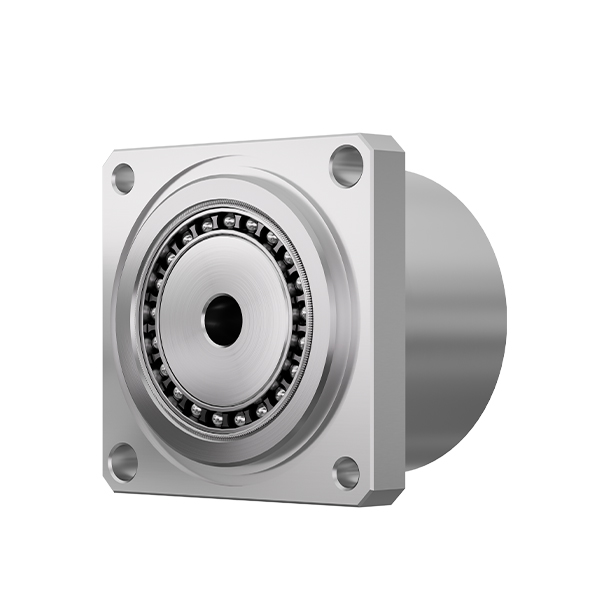

FB Series

FB Series Double Circular Spline Type

FBS-U-C Type

FBS-U-Ⅰ Type

FS Series

FS cup type features a flexspline with external gear teeth in the shape of a cup. Available options include: standard, high-torque, ultra-flat, lightweight.

FSN Lightweight

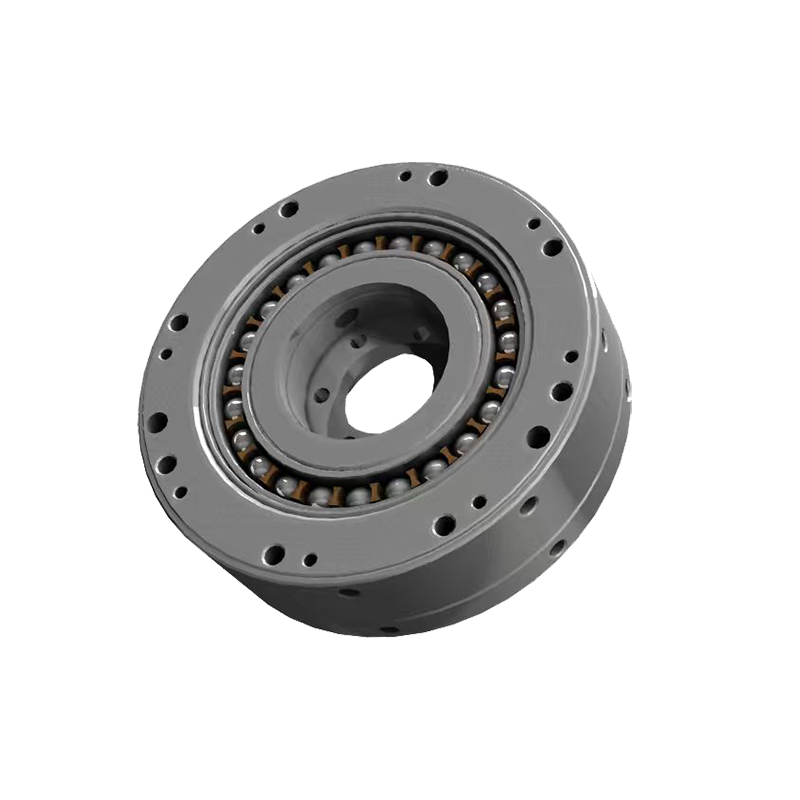

FH Series

The FH Series represents Laifual's versatile lineup of high-precision strain wave gears. Designed for demanding applications, this series offers various configurations—including standard robust models and space-saving hollow shaft types (FHT).

Hollow type FHT

Mini Series

Mini hat type features a brim that looks very similar to a silk hat, hence the name. The brim acts as a perfect mounting surface, leaving a large through hole.

Hat Type FHT-Ⅰ

Quality Assurance & Warranty Policy

Laifual Drive stands behind the quality of every harmonic reducer we manufacture. We provide a warranty period of 12 months from the date of delivery or 2,000 operating hours, whichever comes first. This warranty covers all defects in materials and workmanship under normal use and maintenance.

How to Select the Right Strain Wave Gear for Your Project?

Specifying the precise harmonic reducer is pivotal to achieving peak robot joint performance. To guarantee optimal integration, engineers must rigorously analyze Torque Requirements from balancing continuous to peak loads. Then define the ideal Reduction Ratio from Laifual’s 30:1 to 160:1 range.

Additionally, assess Size & Stiffness profiles to distinguish between our FSS standard or FHT hollow shaft series, and match the Application Environment with appropriate standard or vacuum-grade lubricants. For expert sizing verification, contact our engineering team for a complimentary consultation.

Customization & OEM Services

As a direct manufacturer, Laifual Drive goes beyond standard catalog models. We offer comprehensive OEM/ODM services to fit your unique design requirements:

-

Custom Shafts & Flanges: Modified dimensions for seamless integration.

-

Special Lubrication: High/low-temperature grease or vacuum-compatible options.

-

Reinforced Components: Enhanced materials for extreme load conditions.

Require a tailored configuration? Contact our engineering experts for support.

Frequently Asked Questions