FB Series

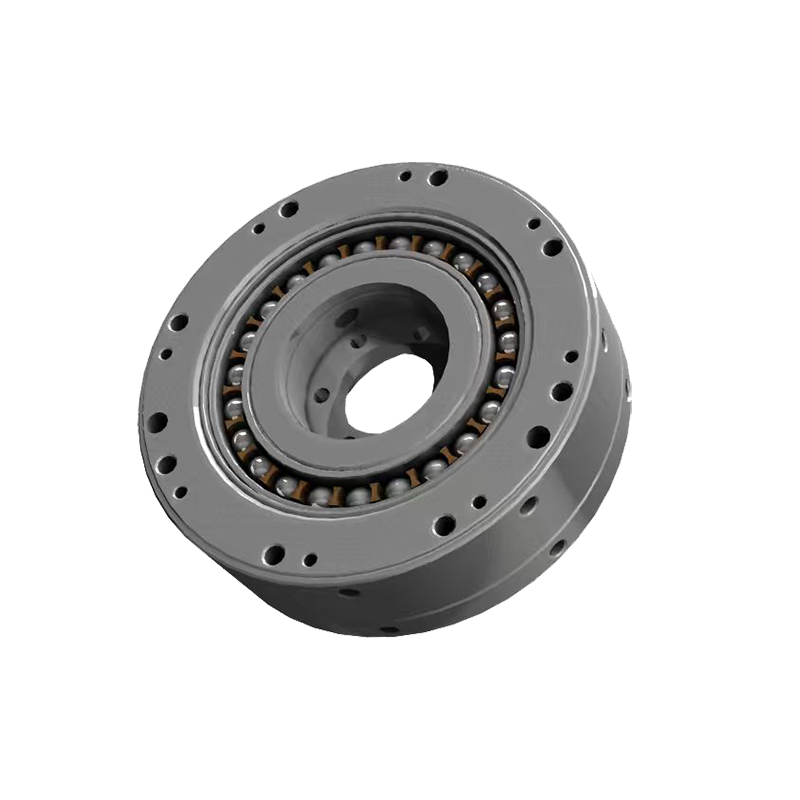

The FB Series Component Type is a specialized flat, thin-profile harmonic drive engineered for applications requiring high torque in limited spaces. While it operates on the same strain-wave principle as the standard cup type, it utilizes a unique four-part structure to achieve an ultra-compact form factor.

To support higher torque capacities, this series features significant structural reinforcements, including widened tooth widths on both the Circular Spline and Flexspline, and a Wave Generator equipped with double-row bearings.

FB Series - Component Type (Flat / High Torque)

Based on the advanced FB tooth profile technology, the FB Series delivers quantifiable performance improvements over standard models:

Ultra-Flat & Thin Profile: Ideal for robotic joints and mechanisms with strict axial space limitations.

High Torque Capacity: Enhanced structural design allows for heavy load handling despite the thin profile.

Compact & Simple: Simplified integration due to the component-set design.

High Precision: Maintains exceptional positioning and rotational accuracies.

Coaxial Design: Input and output shafts are aligned on the same axis.

FBS-U-C Type

FBS-U-Ⅰ Type

Structural Design & Mechanism

Unlike the standard 3-part cup type, the FB Component Type consists of four main parts: The Wave Generator, the Flexspline, and two Circular Splines (S and D). This configuration allows the unit to remain flat while providing high reduction ratios.

1. High Torque Construction

To maximize power density, the FB Series Component Type incorporates specific design optimizations:

Double-Row Bearings: The wave generator utilizes bearings arranged in two lines to withstand higher radial loads.

Widened Gear Teeth: The tooth width of the circular splines and flexspline is increased, expanding the contact area to distribute stress and increase torque transmission capability.

2. Dual Circular Spline Configuration

The operation relies on the interaction between the Flexspline and the two distinct Circular Splines:

Circular Spline S (Static / Fixed Side):

- Teeth Configuration: Has two more teeth than the Flexspline (similar to a standard cup-type circular spline).

- Function: This spline is typically fixed to the housing. It provides the reduction mechanism.

Circular Spline D (Dynamic / Output Side):

- Teeth Configuration: Has the same number of teeth as the Flexspline.

- Function: Because the tooth count is identical, it generates no relative rotation with the Flexspline. It rotates at the exact same speed as the Flexspline and acts as the output drive.

Technical Note: Efficiency Correction

Please note that the efficiency of the reducer varies based on load conditions. An Efficiency Correction Coefficient must be applied when calculating performance:

Low Load Warning: If the actual load torque is significantly smaller than the rated torque, the efficiency value decreases. Please refer to the technical data charts for precise efficiency curves.

Frequently Asked Questions