Rotary Actuator

Simplify your motion control architecture with Laifual’s all-in-one actuator solutions. Whether you are designing mobile robots (AGVs) requiring compact 48V DC drives with EtherCAT/CANopen, or high-power industrial arms needing 220V AC performance with BiSS-C feedback, we have the precise fit. Our actuators integrate high-precision harmonic gears with 17-bit absolute encoders, delivering repeatability of ±20 arc-sec without the hassle of assembly.

Precision Motion Control Solutions

A precision rotary actuator converts electrical energy into exact rotational torque, serving as the critical muscle for advanced automation. Unlike bulky hydraulic or pneumatic systems, Laifual’s electric servo solutions deliver superior control through zero-backlash harmonic gearing and 17-bit absolute encoders. This modular, high-torque design (up to 1530 Nm) accelerates time-to-market and enhances product innovation. Ideal for robotics and aerospace, our actuators ensure reliable angular positioning without the maintenance overhead of fluid-power systems.

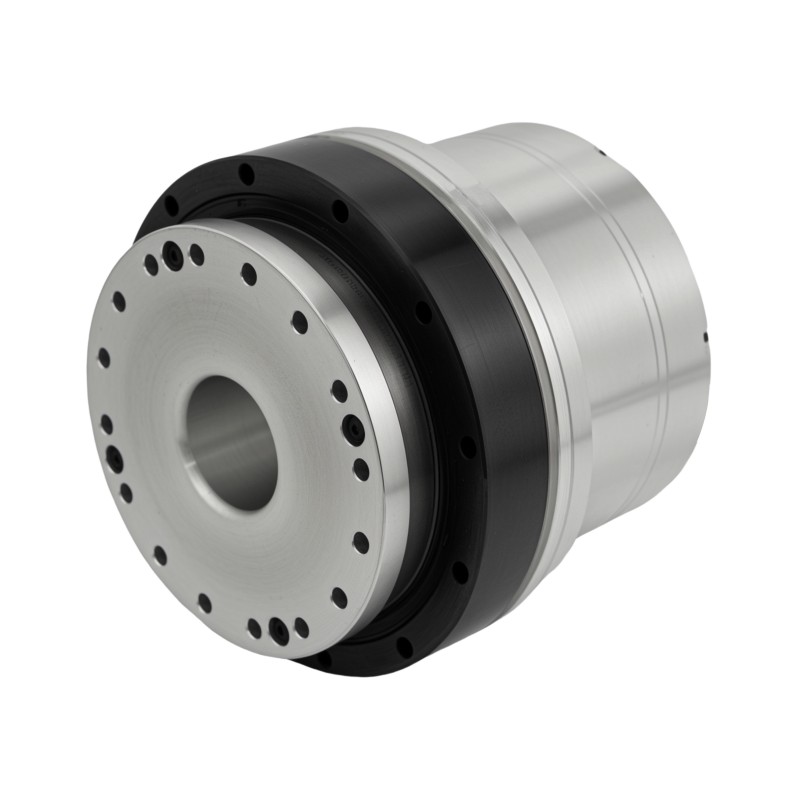

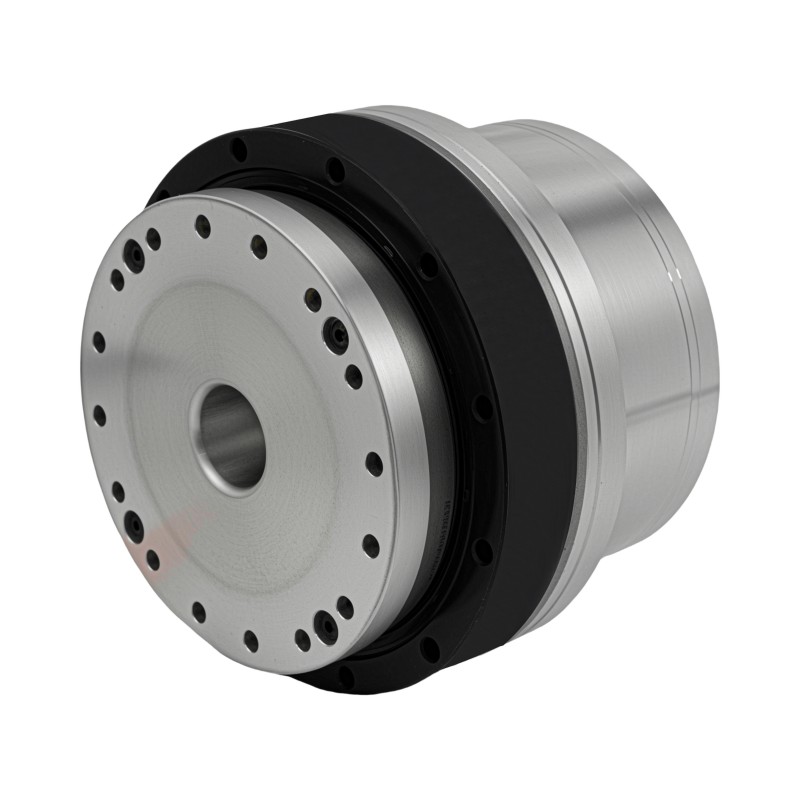

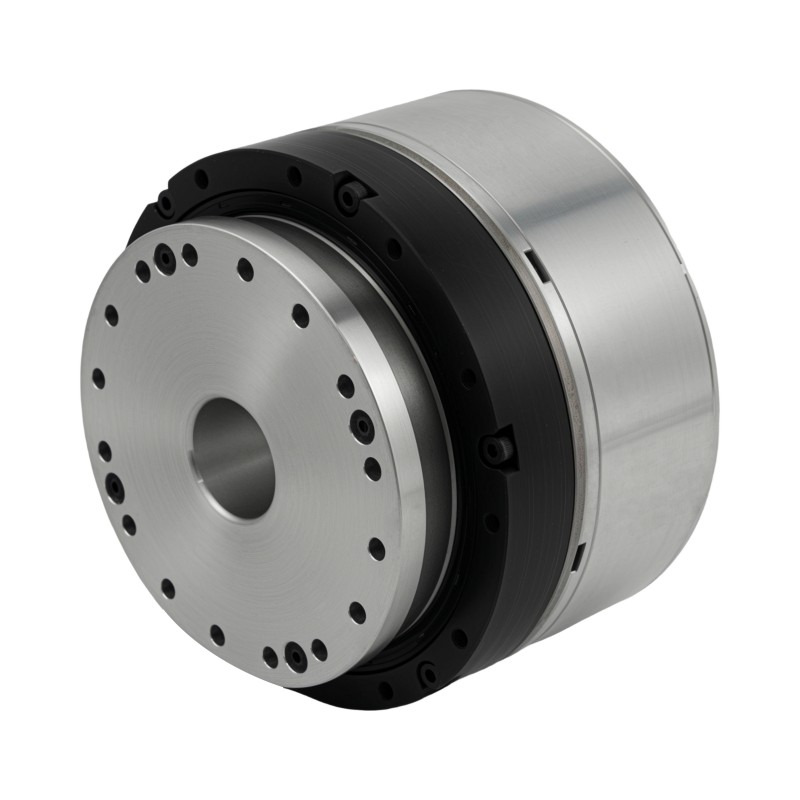

AC Joint Module

The High-voltage Rotary Actuators stand out for their compact design, high precision, and large hollow shaft structure, providing flexibility in system selection, mechanical design, and manufacturing.

High Voltage M170D

High Voltage M142D

High Voltage M110D

High Voltage M90D

High Voltage M80D

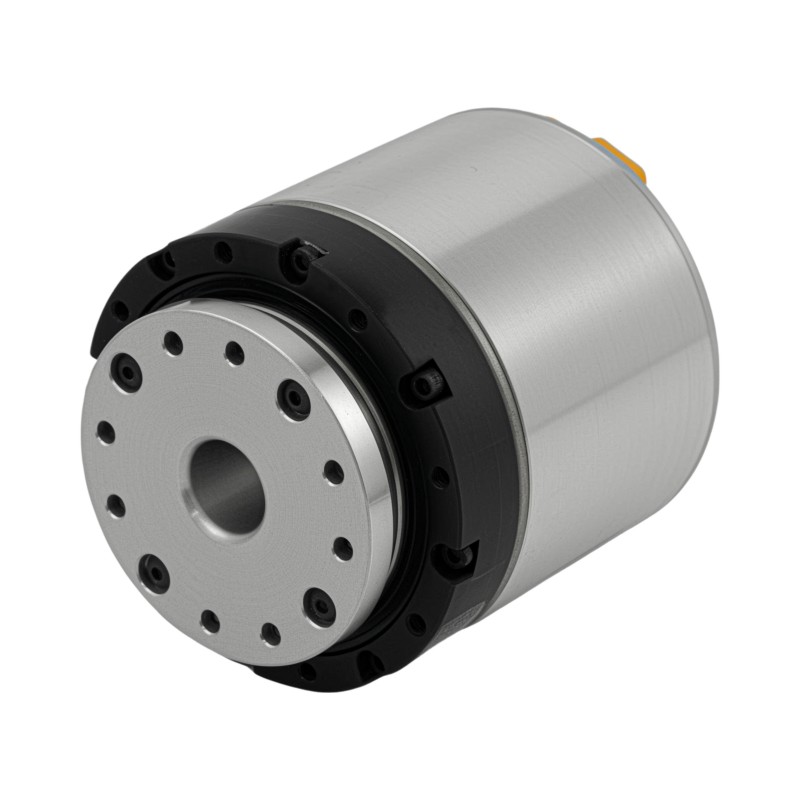

DC Joint Module

Low-voltage rotary actuators are ideal for industries seeking energy-efficient, cost-effective, and scalable automation solutions

Low Voltage L170I-C / L170I-E

Low Voltage L142I-C / L142I-E

Low Voltage L110I-C / L110I-E

Low Voltage L90I-C / L90I-E

Low Voltage L80I-C / L80I-E

Low Voltage L70I-C / L70I-E

Self-Manufactured Core Powerhouse

Laifual redefines vertical integration by manufacturing the entire powertrain in-house. This approach guarantees perfect synergy across every component. We pair our advanced Strain Wave Gears with high-efficiency frameless motors to create a unified system. These motors leverage high-permeability silicon steel and high-remanence magnets to maximize torque density.

To ensure thermal stability, we apply a specialized epoxy resin potting process to the stator. This technique significantly enhances heat dissipation and insulation over standard methods. Powered by an innovative servo drive with a 600MHz main frequency, this all-in-one solution delivers robust processing power and high dynamic response for automation.

Closed-Loop Control & Connectivity

Exceptional motion control requires more than mechanical strength; it demands intelligence. Our system adopts advanced closed-loop control technology to ensure precise position retention. It features strong interference immunity, fully passing EMC Level 3 testing for reliable operation.

For connectivity, the actuators natively support mainstream protocols like EtherCAT and CANopen. This native support simplifies integration into complex robotic systems. Designed for efficiency, our electronics feature ultra-low static power consumption (100mA). With a wide working voltage range (2V-5.5V), we maintain high-precision control while minimizing energy usage.

T-Type Joints & Reliable Braking

Innovation extends to our physical architecture with the new T-type Rotary Actuator design. This configuration delivers smoother, more precise performance specifically for robotic articulation. The compact structure incorporates a large hollow shaft for simplified cabling.

Crucially, we utilize our proprietary electromagnetic brake technology. We use advanced friction plate materials to effectively lower noise and extend component lifespan. The brake coils also benefit from epoxy resin potting for superior thermal management. Laifual guarantees a reliable structural design that withstands continuous industrial operation with minimal temperature rise.

Frequently Asked Questions